By using our website, you agree to the use of cookies as described in our Cookie Policy

Various successful prototypes and ideas in the works to becoming real solutions during COVID-19 crisis

Basalt-based nonprofit helps facilitate national solutions during COVID-19 crisis

Aspen Times Serving Aspen and Snowmass Village, CO

Maddie Vincent

A pair of protective glasses that don’t fog up. A belt with reusable compartments that can hold various sanitizing and personal protective products, making the items more easily accessible. An app that helps check for COVID-19 symptoms before someone leaves their home.

These are just a few of the ideas and innovations presented via Zoom on Sunday as part of the COVID-19 Maker Challenge, a series of five weeklong make-a-thons that aim to quickly produce effective, cost-efficient ways to help front line and essential workers carry out their jobs safely amid the coronavirus pandemic.

For roughly two hours Sunday, teams of engineers, designers and other professionals from various fields presented their innovations, which were designed to address specific challenges nursing home and long-term care facilities are facing amid the pandemic as facility employees work to keep themselves and their elderly residents safe.

“Over the course of this last week, we’ve been joined by around 100 engineers, software programmers and other subject matter experts who are all volunteering their time to learn about these challenges that central workers face,” said Dallas Blaney, executive director of Challenge America, a local nonprofit and one of the organizations heading the COVID-19 Maker Challenge.

“These teams have done a deep dive into the nature of these problems, have worked to develop innovative designs as solutions to these particular challenges, and have gone one step further by actually building working prototypes based on their designs.”

Challenge America, which is based in Basalt, is a national veterans-focused nonprofit that works to leverage technology and the creative arts to improve the lives of military service members, veterans and their families, Blaney said.

The nonprofit has worked closely with the Veterans Health Administration (VHA) Innovation Ecosystem — a program that collaborates with U.S. Department of Veterans Affairs health care workers, veterans, educators and private industry to facilitate health care innovations for veterans — in recent years to host a recurring technology challenge program called “Challenge America Makers for Veterans.” The program is geared toward coming up with innovative hardware and software products to improve the lives of injured veterans, Blaney said.

But with the COVID-19 crisis affecting most Americans’ lives, including veterans’ this year, Blaney and Danielle Krakora with VHA Innovation Ecosystem said the VA’s “fourth mission” to improve the nation’s preparedness and response to war, terrorism, natural disasters or a national emergency like the global COVID-19 crisis has been activated — pushing both partnering veterans organizations to refocus their maker program to support frontline or at-risk workers and their industries during the crisis and to help mitigate the spread of the novel coronavirus.

“We wanted to create meaningful solutions to keep our veterans and employees safe, but also to contribute to the same in our communities for other essential workers on the front lines,” Krakora said Sunday during the Zoom event.

Through the five targeted programs that make up the overall COVID-19 Maker Challenge, Blaney said participants from private industry, leading research universities, federal agencies like the VA, and nonprofits have one week to hash out “solutions” that can be created rapidly and cost effectively through manufacturing processes like 3D printing. Each solution must help solve the specific issue each team is prompted with at the start of the make-a-thon and support specific frontline workers or sectors impacted by the COVID-19 crisis.

The tools and innovations presented Sunday to help nursing home industry workers specifically were part of the third COVID-19 Maker Challenge program or make-a-thon. The first two programs worked to support first responders and custodial and housekeeping staff, and the final two will focus on coming up with solutions for at-home caregivers and to help with disaster relief in places hard-hit by the pandemic like the Navajo Nation, Blaney said.

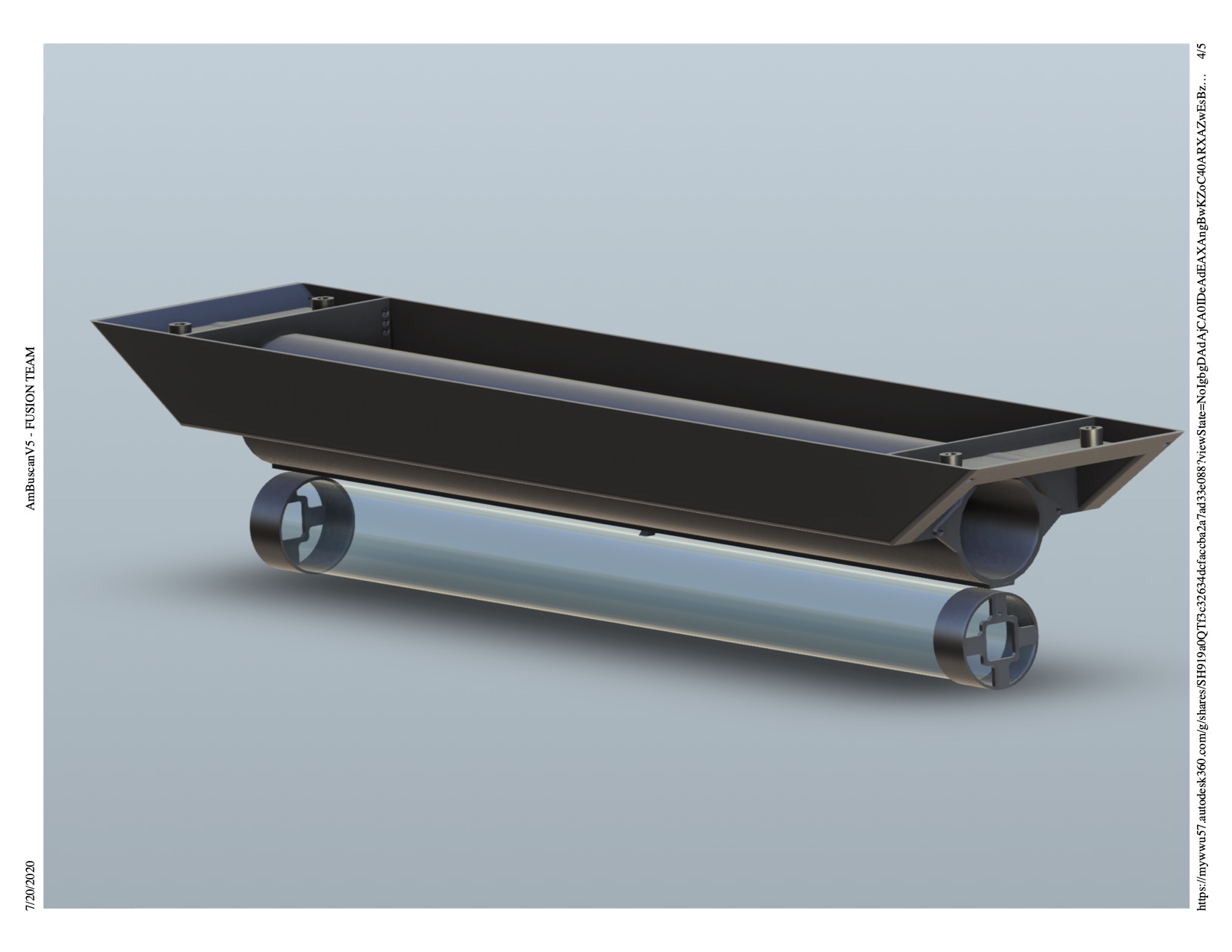

Various successful prototypes and ideas in the works to becoming real solutions have come out of the challenge so far, Blaney said, including the Ambuscanner — a UV-C light scanning device that can help efficiently decontaminate things like ambulances, elevators, bathrooms, taxi cabs, police cruisers and a multitude of other confined public spaces, reducing the risk of contracting COVID-19 and other infectious diseases.

On a recent morning, De’Andre Wells, a retired U.S. Army sergeant and founder of American Group Contrax out of Maryland; Roger Janssen, president of 3DX Industries out of Washington; and Ben Holmgren of the Bellingham Makerspace, all members of the Ambuscanner design team, talked over the phone about their UV-C light disinfector, which the team is in the process of testing and building a finalized prototype for.

“Our challenge with Challenge America was, ‘How do you decontaminate the backside of an ambulance?’” Janssen said. He went on to explain that the team worked closely with a fire department in Ohio to develop its solution.

“Part of the whole goal was to decrease the response time for the ambulances because after the COVID breakout they had to decontaminate the inside of the ambulance after each call, which took an extensive amount of time. With (our) UV light cure, they can be decontaminating while they’re going on their next call.”

However, the three men said they envision the Ambuscanner being used to disinfect a variety of confined spaces beyond just ambulances and are excited to be a part of a solutions-based maker challenge that utilizes American innovators and manufacturers.

“There’s opportunity in chaos, … there’s a real need right now for the resiliency of America to return. We need strength, we need to be restoring and we just decided we’re going to be that for America, we are going to be the strength of bringing manufacturing back to the states,” Wells said of the CureX Corporation, a new company he and his fellow maker challenge teammates created recently to produce the Ambuscanner and other “engineering solutions for our nation’s toughest challenges.”

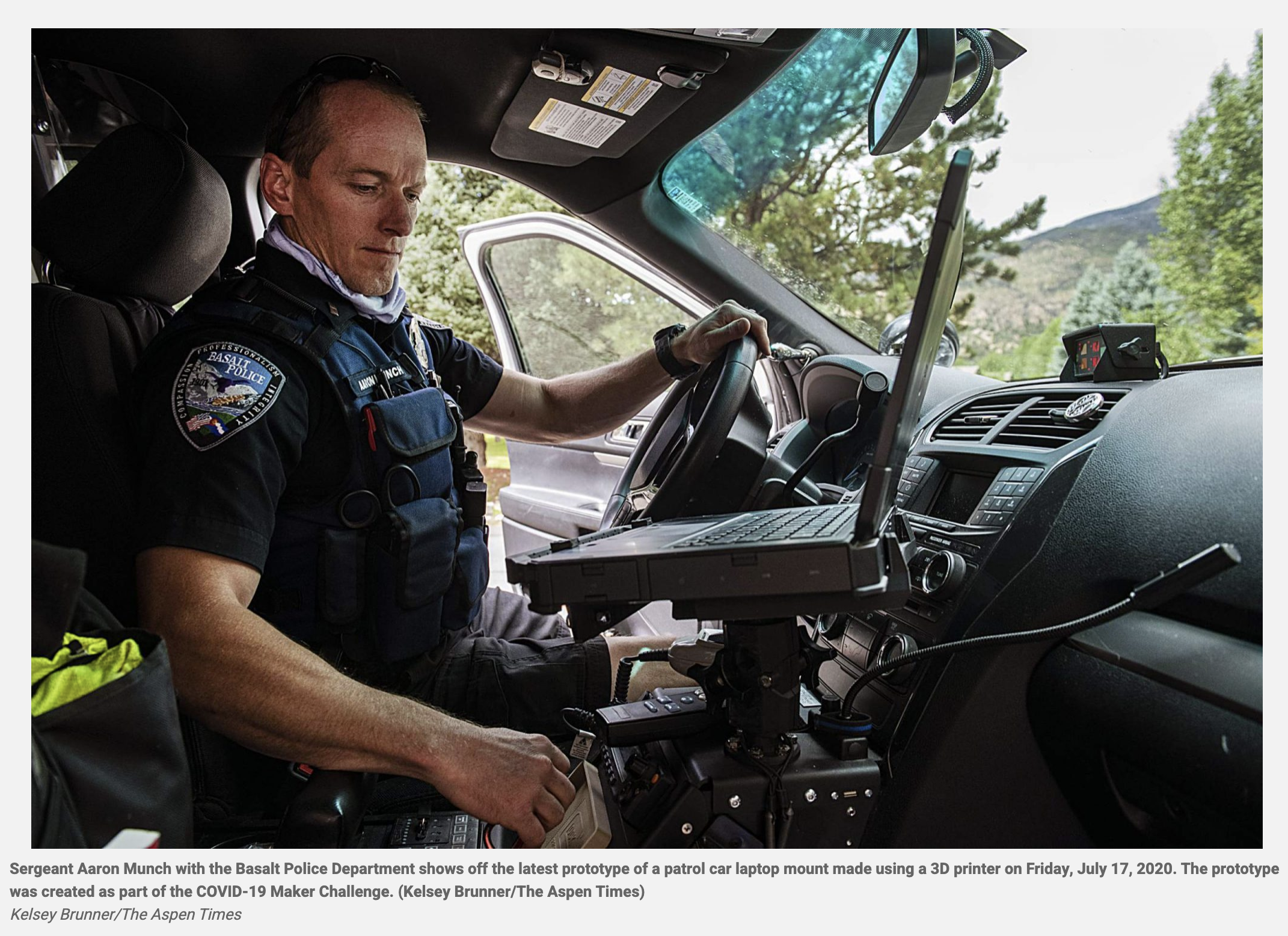

A little closer to home, another COVID-19 Maker Challenge project that is in the final design and manufacturing phases is the “police car laptop mount” — an affordable laptop mount made using a 3D printer that officers working with more rural police departments and law enforcement agencies can use to complete their office work in a socially distanced way from the safety of their patrol cars.

Noah Mostow, project leader and an advanced manufacturing masters student at Colorado School of Mines, is working closely with the rest of “Team Connected Cruiser” to perfect the patrol car laptop mount prototype, using feedback and patrol car specifics from the Basalt Police Department to guide them.

Mostow said while it hasn’t been easy virtually collaborating with a team of people from all across the country, he and three of his classmates who also were part of the COVID-19 Maker Challenge feel grateful to have the opportunity to give back to the community in a positive way and to gain experience working with professionals from different backgrounds to create a product that will be utilized in the field quickly.

For Sgt. Aaron Munch with the Basalt Police Department, having affordable, durable patrol car laptop mounts would help officers who are constantly coming into contact with people keep more distance from each other, mitigating the potential spread of COVID-19 among department staff.

He said he and his staff have sent photos and videos of their patrol vehicles to help the COVID-19 Maker Challenge team and are excited to see the final prototype when it’s ready.

“It’s been amazing to see what the team has come up with. It’s well outside what we thought was possible,” Munch said. He went on to say this was the first time the Basalt Police Department has worked with Challenge America during a make-a-thon and that he and his staff would be open to doing it again.

Although Challenge America is a national nonprofit, Blaney — a Carbondale local, U.S. Navy veteran and “recovering professor” — said the organization is dedicated to keeping its services and solutions like those created during the COVID-19 Maker Challenge localized for Roaring Fork Valley residents when possible.

He said he’s excited about the solutions and innovative ideas being created through the current maker challenge and would love to see more Roaring Fork Valley locals get involved in the last two programs.

“Even though we’re a national nonprofit, when we’re trying to come up with these challenges and solutions to the extent that we’re able, we try to do things that benefit our community here,” Blaney said.

If you are interested in getting involved in the COVID-19 Maker Challenge, submitting your ideas or learning more about the upcoming make-a-thons, visit covid19makerchallenge.com.